Flexible Material Abrasion

The Taber® Flexible Material Abrasion Kit can be used to evaluate the abrasion resistance of most flexible films and packaging materials. Use of this kit requires the Taber Linear Abraser Model 5750 and T-Slot Universal Table (both sold separately).

Engineered thermoplastic films are commonly used in packaging food products, sterilized medical devices and other products. However during distribution and handling, movement between the product and packaging film or secondary packaging may occur. Shock, vibration and/or repetitive rubbing allows the product to abrade the cross-section of the film, thus increasing the potential for the packaging to be compromised. For food products, this may impact freshness whereas for medical devices, the sterility barrier may be destroyed. The Flexible Material Abraser Kit allows you to evaluate which packaging options will best withstand the typical events associated with product handling, distribution and storage of your product.

Description

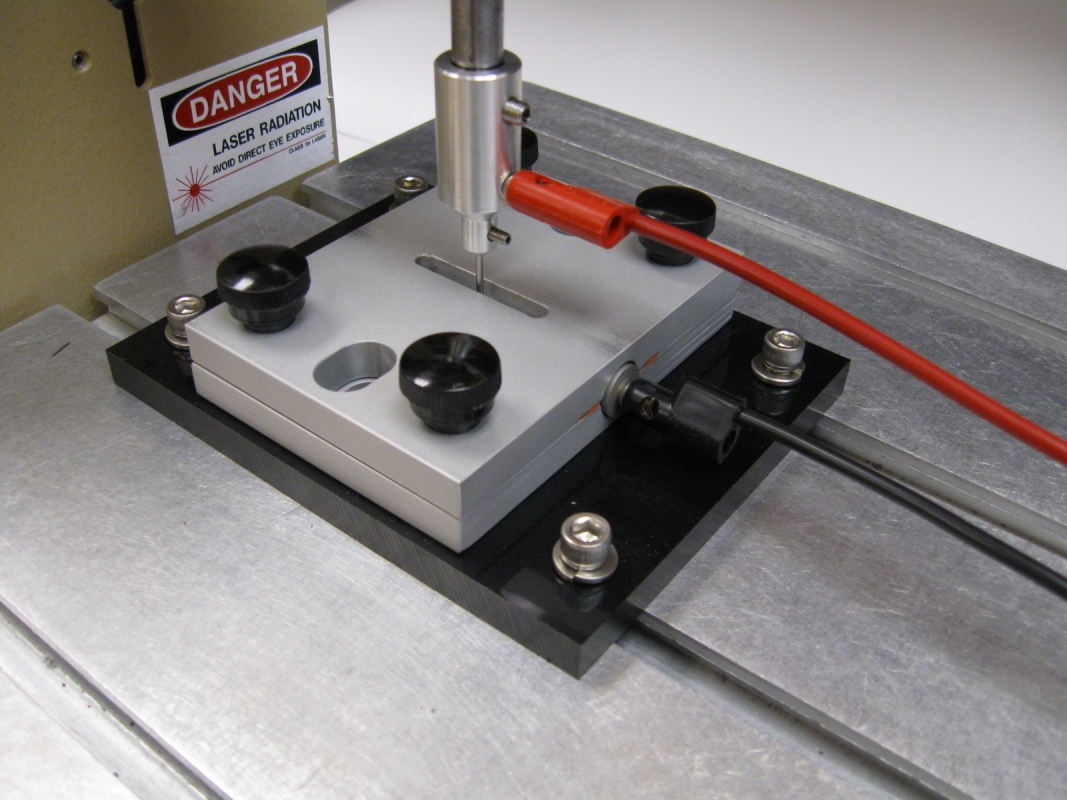

The Flexible Material Abrasion Kit uses a linear rubbing action of a 1.5 mm diameter hemispherical needle stylus to abrade the cross-section of a test specimen.

Test specimens are approximately 38 mm (1.5 inch) wide and 50 mm (2 inch) long. After being positioned on the top of a 12 mm cylindrical mandrel, the specimens are secured in place with a top plate. Two rubber strips incorporated in the top plate press down on the sides of the specimen to minimize slippage and ensure the specimen is held rigidly during testing.

A cutout in the top plate enables the needle stylus to make contact with the test specimen. Under controlled conditions of pressure and abrasive action, the stylus travels back and forth over the specimen on the centerline apex of the mandrel. When breakthrough occurs, the test is automatically stopped.

Note: This test may not be suitable for films that stretch and generate a ripple during testing, or that have a thickness greater than 0.25 mm (0.010 inch).

Abrading Tool

The needle stylus has a 1.5mm diameter tip and is made from stainless steel, which has a hardness of Rockwell C55 to C61 and a surface finish of 8 rms.

Evaluation

The number of cycles to breakthrough provides an indication of abrasion resistance.