Linear Abraser-Motor Noise

For companies that perform high cycle testing with their Model 5750 Linear Abraser , increased motor noise may be observed with instruments that were shipped during 2011—2016. In June 2016, Taber Industries completed a study in which extensive testing and research was conducted to study this issue. An independent laboratory confirmed the root cause was electrically induced pitting of the motors ball bearings and raceway which was induced by the PWM drive circuit in the motor driver. The issue was caused when stray electrical currents arc through the bearings. Electrical discharge machining (EDM) created thousands of microscopic pits in the bearing’s race and over time, the bearings degrade. The result was increased friction and noise. Eventually the rolling elements can cause fluting damage to the bearing races and the grease can become contaminated due to the free particles that result from the surface damage. Operation of the Linear Abraser was NOT affected by this phenomenon, and test results were not influenced.

Taber proactively contacted customers(distributors) who purchased (sold) an instrument during this time period to inform them a replacement motor kit was available through Taber Industries. This kit includes a right angled motor with the bearings mounted in a vertical plane; an integrated bearing protection kit which includes a snubber circuit that discharges shaft voltage through the attached kit rather than through the bearings; and a modified mounting bracket. Detailed instructions are provided to ensure easy installation (reference p/n 135433).

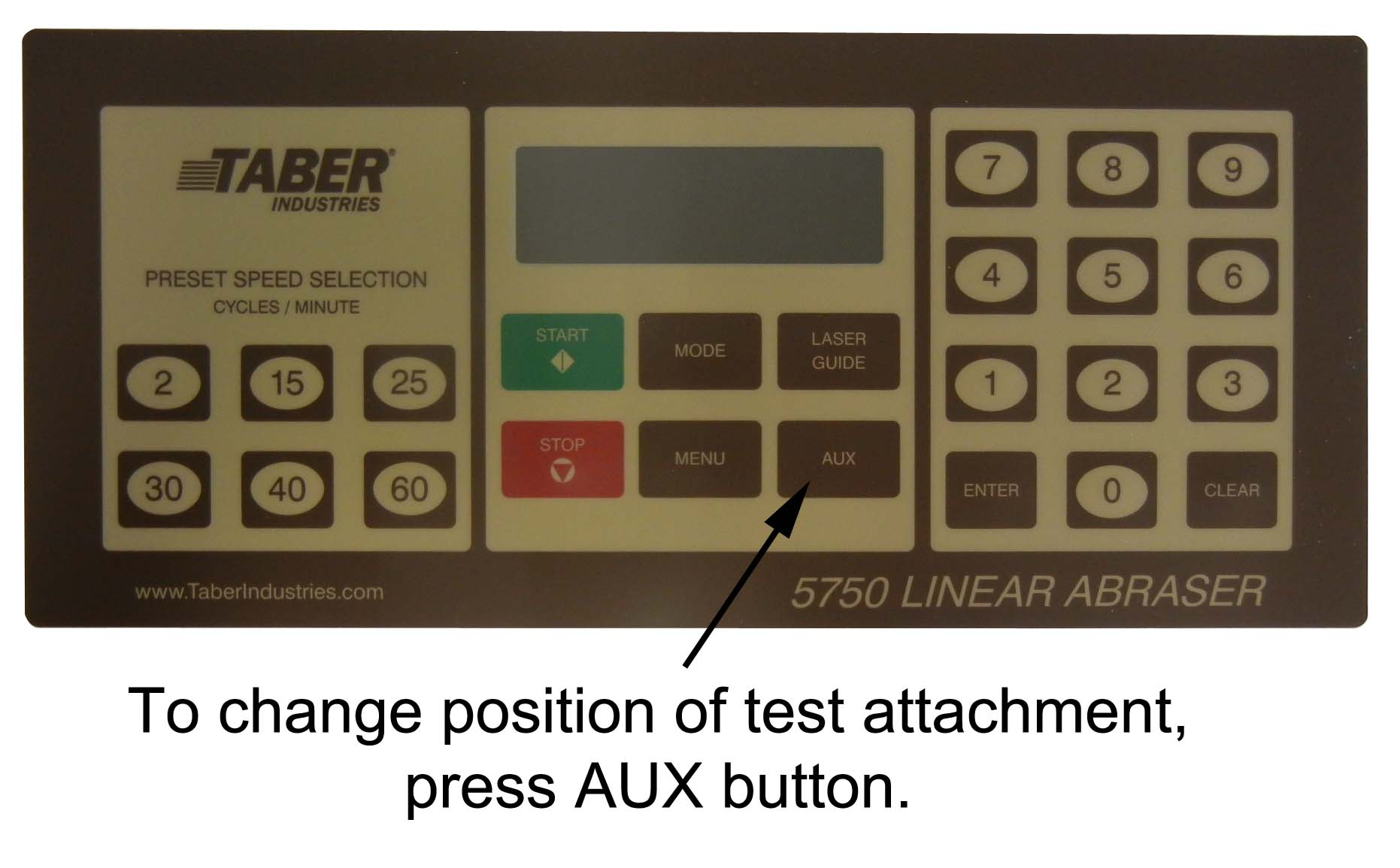

Note, this replacement motor cannot be repositioned by hand like the original motor. To change the location of the test attachment, press the AUX button—this will advance the test system at a rate of 2 cycles per minute. Press the AUX button a second time to stop at the desired position.